Seneca

The collaboration between IMA and AImageLab involves the detection of anomalies in time series data of various kinds. In the first case, the data measures the vibration of some engines, using accelerometers placed on them, with the aim of detecting wear and possible failures. In the second case, the aim is to predict in advance the possibility of a production cycle failure, so that the operator can be warned in advance and appropriate countermeasures can be taken.

Accelerometers

The fundamental data on which to carry out the analysis is the vibration of each engine, measured by means of an accelerometer applied directly to the body of the engine itself. IMA's interest lies in being able to detect any defects in the engines and estimate the degree of wear over time. Accelerometer values are sampled at a high frequency and are often influenced by noise and various sources of interference (other nearby engines influencing each other). For this reason, it was decided to work in the frequency range by applying Fast Fourier Transform (FFT) as a pre-processing to the data. This method is consistent with what is available in the literature regarding the detection of anomalies in high-frequency time series.

Faults in the real world

In many cases it is not possible to know in advance the effect of degradation and wear on an engine. However, if one were to observe that each unit emits a spectrum which is totally different from any other (like a kind of engine "signature") this would make it possible to measure how much the current behaviour is deviating from its normal working conditions, effectively producing an estimate of engine wear. To test this hypothesis, a series of experiments were carried out with the aim of distinguishing between different engines just by observing their vibration. Initial tests show that the highest frequency range (≥ 2000Hz) allows the problem to be solved easily.

Defining faults from known datasets

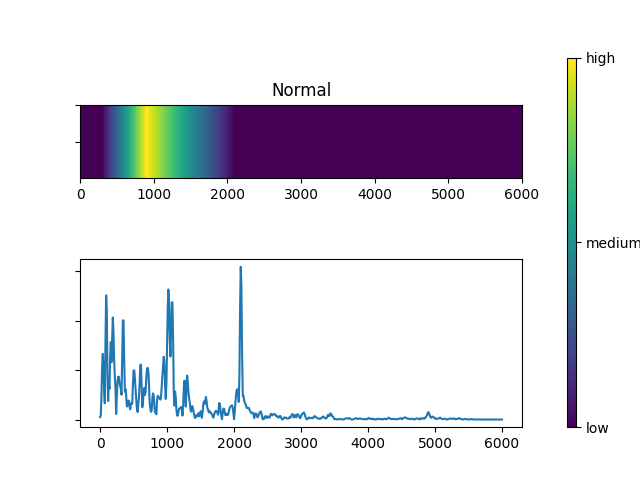

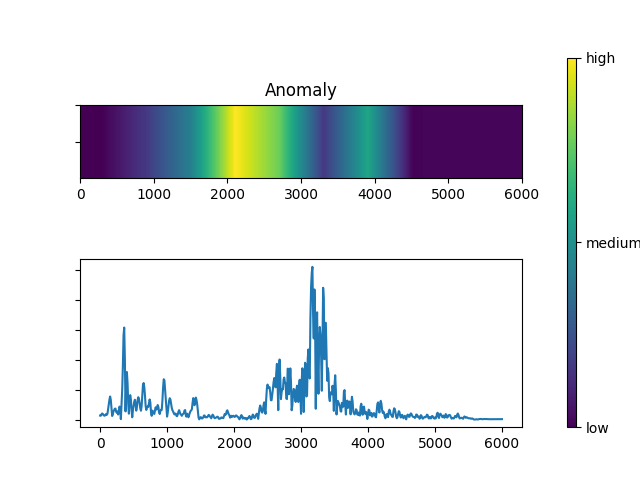

According to the available literature, most of the problems associated with engine wear are due to defects or failures in the ball bearings. Initial efforts were therefore made from publicly available datasets, observing the effects of this class of anomalies on engine vibration. Given an algorithm capable of solving the problem effectively, it is possible to observe which portions of spectrum the model focuses on most to distinguish an input as normal or abnormal. In the former case, in the first figure, it can be seen that most of the weight is placed on low frequency ranges, while in the case of anomalies (the second figure) the most important activations are those related to intermediate frequencies.

Remaining useful life estimation

Remaining life estimation (RUL prediction) is a variant of the previous problem, in which the vibration of an engine is recorded until one of its components fails. This type of problem is in line with the requirements of IMA, since the aim is to produce a model that can predict the remaining life time given the current vibration (in percentage form).

The model

Given the difficulty of having anomaly data available during model training, an unsupervised approach was chosen, in which only the structure of the normal data is learned and the output of the model is an estimate of how consistent the input is with its internal representation. In a second step, the application of a threshold will allow to distinguish outliers. In fact, since the latter are not seen during training, a much lower estimation value than the normal data is expected.

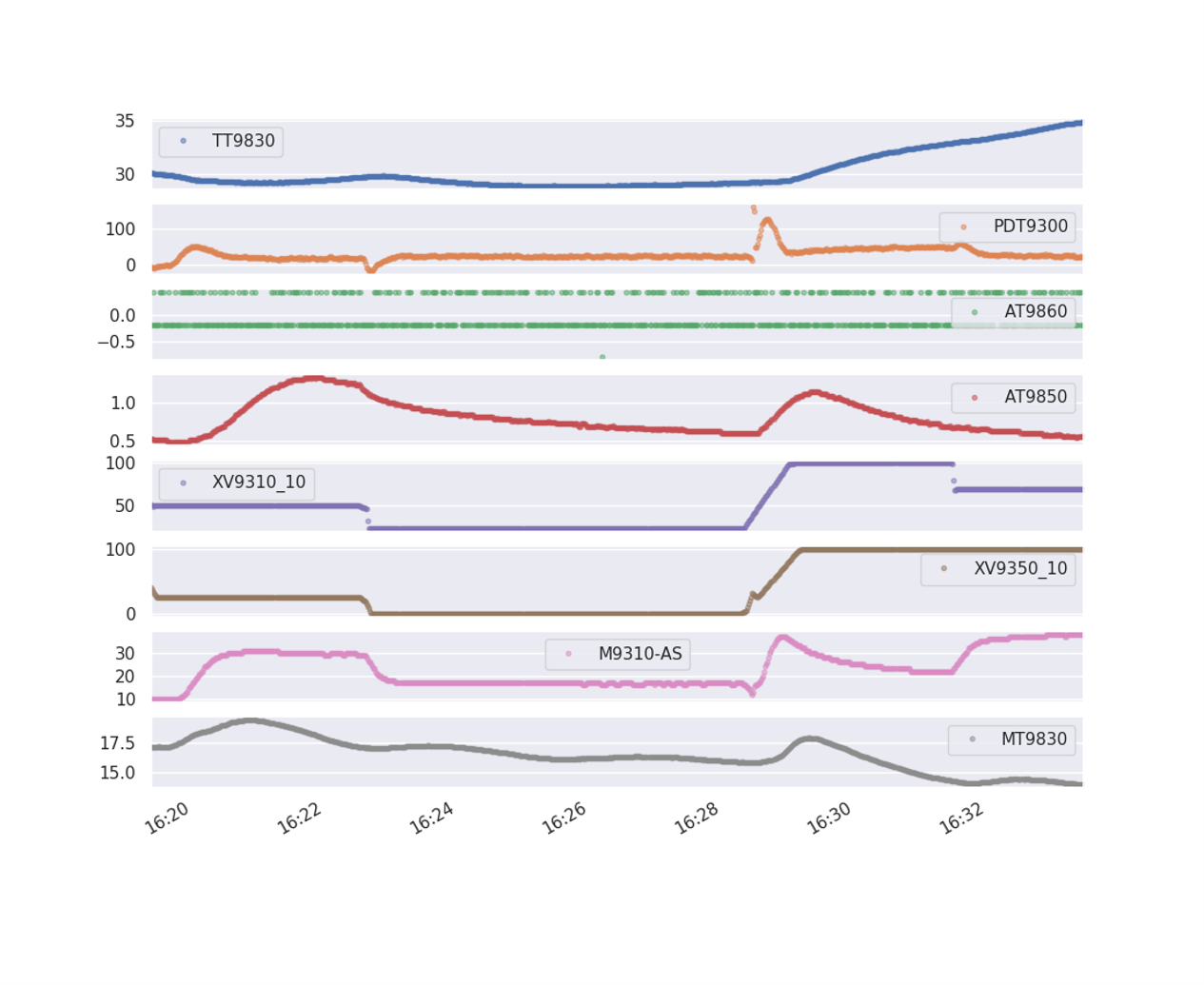

Process variables

The production of particularly complex goods is often characterised by well-defined and particularly rigid cycles, in which a single unforeseen event could compromise the entire production cycle.

IMA's interest lies in the possibility of monitoring its machines and predicting in advance the possibility of a production cycle failure, by observing the trend of environmental and physical quantities of the machine.

To enable the operator to take countermeasures to limit damage to the product, an ideal model should be able to provide an accurate prediction early enough and indicate why a fault has been reported. To derive a model in line with expectations, it is first necessary to have sufficient data from the machines concerned. For this reason, a great deal of work is being done to collect and annotate data.

Project Info